| China Textile Machinery Industry :Innovation Drives High-quality Development |

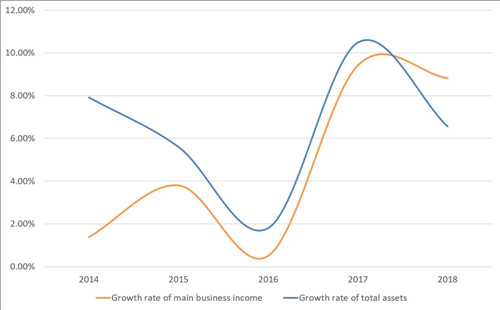

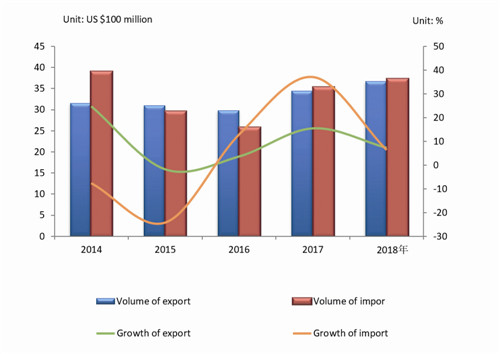

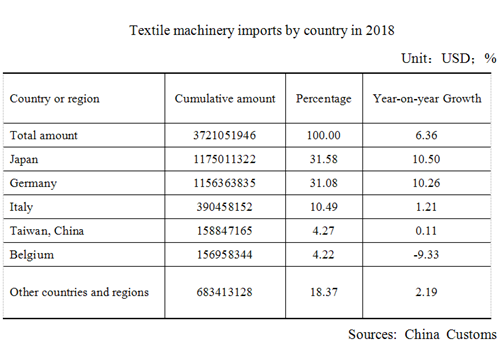

By China Textile Machinery Association(CTMA) In 2018, the pace of industrial upgrading in the textile machinery industry was accelerated. The product development has shown obvious characteristics in many aspects, such as new type and high efficiency, low-energy consumption, flexibility, automation, digitalization and intellectualization. Technological innovation and structural adjustment have supported the stable growth of the industry, and the industry has gone well overall both in quality and efficiency. Smooth operation of the industry In 2018, the main business income of the textile machinery industry reached 91.169 billion Yuan, an increase of 8.82% compared with the same period of last year. The assets totaled 101.796 billion Yuan, an increase of 6.55% compared with the same period of last year. Growth rate of main business income and total assets in China textile machinery industry  The total profit of the textile machinery industry in 2018 reached 6.833 billion Yuan, an increase of 5.12% compared with the same period of last year. The profit level of the industry continued to improve because of the deepening of the structural adjustment in the textile machinery industry, the improvement of the product and technology, the increasing of the prosperity in the downstream textile industry, the further stability of the domestic and overseas markets of textiles, and the increasing cost control by enterprises. Continuous growth of imports and exports According to the statistics of China Customs, the imports and exports of China’s textile machinery totaled US $7.387 billion in 2018, an increase of 6.78% compared with the same period of last year. Among them, the imports of the textile machinery totaled US $3.721 billion, an increase of 6.36% compared with the same period of last year, and the exports totaled US $3.666 billion, an increase of 7.20% compared with the same period of last year. In short, exports grew faster than imports.  In terms of exports, with the acceleration of the industrial transfer of textile industry, the market demand has increased in Southeast Asia, South Asia, Africa and other foreign countries. The export volume of textile machinery industry has reached a record high. The innovation and quality improvement of domestic textile machinery products have greatly enhanced the international competitiveness of textile machinery industry. In 2018, textile machinery exports reached US $3.666 billion, with a growth of 7.20% compared with the same period of last year. Exports to India, Vietnam, Bangladesh, Indonesia, and Turkey accounted for 51.40% of the total exports. Among the export products, knitting machinery accounted for 26.08%, ranking first, followed by dyeing and finishing machinery, auxiliary devices and spare parts, spinning machinery, weaving machinery, chemical fiber machinery and non-woven machinery. Imports and exports of the textile machinery industry  In terms of imports, Japan, Germany, Italy, Taiwan China and Belgium were the main countries and regions for the imports of textile machinery in 2018, with the import volume totaling US $3.038 billion, an increase of 7.35% compared with the same period of last year, accounting for 81.63% of the total imports. Among the import products of textile machinery, the auxiliary devices and spare parts ranked first, with a total import volume of US $899 million, an increase of 7.73% compared with the same period of last year, accounting for 24.15% of the total imports. Among the seven categories of products, import of chemical fiber machinery and weaving machinery increased relatively higher.  Situation of subdivided fields The development of textile industry has a direct impact on the market of the textile machinery industry. With the differentiation of the demand in various textile industries, the market sales situation of each segment in the textile machinery industry has varied a lot since 2018. Spinning machinery On the one hand, more attention has been paid to market segments, on the other hand, labor using and product quality improvement of textile enterprises have been taken great care. In 2018, overall operation of the spinning machinery industry was relatively stable. Users were still enthusiastic about the short-process equipment. With the increasing variety and count of spinning with short-process equipment, the trend of partially replacing of ring spinning was more obvious. Weaving and preparation machinery, The adaptability of weaving and preparation machinery has been further improved. Domestic machinery models have been transferring to high-speed ones with attention paid to gas-saving, energy-saving and consumption-reducing. In 2018, along with the industrial transfer, upgrading process acceleration, and continuous growth of the demand for chemical fiber filament fabrics, sales volume of water jet looms and air jet looms increased significantly. While the sales volume of high-speed rapier loom slowed down because of the environmental protection policy, etc. Knitting machinery Diversified development trend was seen. Circular knitting machine, flat knitting machine and warp knitting machine learnt from each other while developed in their respective fields. With the improvement of equipment technology, the cross-border and innovative products used for garments, household and industrial textiles have been constantly emerging. The market of flat knitting machine, circular knitting machine and warp knitting machine ran smoothly as a whole. Printing and dyeing equipment The energy conservation and emission reduction, clean production and digital technology application continued to be enhanced. In 2018, the market of printing and dyeing equipment, together with finishing equipment was in good condition. The market of traditional printing machine basically remained stable. The combination printing machines of digital + circular screen or digital + flat screen, with the characteristics of traditional and digital printing machines, sold well. The market of setting machine has kept the growth trend in the recent years. Chemical fiber machinery Enterprises have conducted in-depth research in the aspects of integration, networking, informatization, intellectualization, as well as energy conservation and consumption reduction, which can provide more complete chemical fiber production system solutions for manufacturers. Overall, the production of chemical fiber machinery maintained a good momentum in 2018. What’s more, the production and sales volume of various major equipment increased significantly compared with that of last year. Non-woven machinery Enterprises have significantly improved the awareness of manufacturing accuracy and automatic control of processing. The organic combination in the fields of non-woven technology, material application and mechanical manufacturing, has further narrowed the gap between China and overseas countries. The growth rate of non-woven machinery has showed declining trend in 2018 after experiencing the high growth speed in the past few years. Industry development prospect in 2019 Looking forward to the year of 2019, although facing profound changes in the international environment and increasing downward pressure on China’s economic operation, the overall stable macroeconomic environment of China and continuous upgrading of domestic market demand will still provide impetus for the innovative development of the textile industry. In the future, the textile machinery market will still focus on the new production capacity and stock capability upgrading and reconstruction brought by the industrial transfer of domestic textile industry. Meanwhile, with the acceleration of global textile industrial transfer and the active expansion of overseas market by Chinese textile machinery enterprises, the export in textile machinery industry is expected to maintain a growth trend. In short, China’s textile machinery industry in 2019 will continue to focus on the transformation and upgrading needs of the textile industry, actively adjust the structure of products, work from intelligent manufacturing, efficiency improvement, cost reduction, greening and environmental protection, so as to promote high-quality development of the industry. |

| 相关文章 |